Getting Started with Fab Labs

What is a Fab Lab?

A Fab Lab, or digital fabrication laboratory, is a place to play, to to create, to learn, to mentor, to invent: a place for learning and innovation.

Fab Labs provide access to the environment, the skills, the materials and the advanced technology to allow anyone anywhere to make (almost) anything.

What is the Fab Lab Network?

The Fab Lab Network is an open creative community of fabricators, artists, scientists, engineers, educators, students, amateurs and professionals located in more than 100 countries and 1,750 Fab Labs across the globe.

From community based labs to advanced research centers, Fab Labs share the goal of democratizing access to the tools for technical invention. This community is simultaneously a manufacturing network, a distributed technical education campus, and a distributed research laboratory working to digitize fabrication, inventing the next generation of manufacturing and personal fabrication.

How to start a Fab Lab

Check out all of the resources we have on setting up a Fab Lab and becoming a part of this global community:

Fab Lab is the educational outreach component of MIT’s Center for Bits and Atoms (CBA), an extension of its research into digital fabrication and computation. A Fab Lab is a technical prototyping platform for innovation and invention, providing stimulus for local entrepreneurship. A Fab Lab is also a platform for learning and innovation: a place to play, to create, to learn, to mentor, to invent. To be a Fab Lab means connecting to a global community of learners, educators, technologists, researchers, makers and innovators- -a knowledge sharing network that spans 100 countries and 24 time zones. Because all Fab Labs share common tools and processes, the program is building a global network, a distributed laboratory for research and invention.

A Fab Lab is comprised of off-the-shelf, industrial-grade fabrication and electronics tools, wrapped in open source software and programs written by researchers at MIT’s Center for Bits & Atoms. Originally designed for communities as prototyping platforms for local entrepreneurship, Fab Labs are increasingly being adopted by schools as platforms for project-based, hands-on STEM education. Users learn by designing and creating objects of personal interest or import. Empowered by the experience of making something themselves, they both learn and mentor each other, gaining deep knowledge about the machines, the materials, the design process, and the engineering that goes into invention and innovation. In educational settings, rather than relying on a fixed curriculum, learning happens in an authentic, engaging, personal context, one in which students go through a cycle of imagination, design, prototyping, reflection, and iteration as they find solutions to challenges or bring their ideas to life.

As support for advanced technical education and to provide a training path for new fab lab managers, Fab Academy , an internationally distributed campus for technical education, has emerged from the Fab Lab program. The Fab Academy provides instruction and supervises investigation of mechanisms, applications, and implications of digital fabrication.

In addition to Fab Academy, SCOPES-DF, fueled by collaboration and community, has the power to transform STEM learning in diverse educational settings through digital fabrication technologies and practices found in a Fab Lab or makerspace. We are building curricular frameworks, professional development resources, and evaluation tools around digital fabrication that can catalyze STEM learning in the classroom. This new platform will enable fabbers, makers and educators to collaborate and interact in a Community of Practice and promises to expand STEM learning and teaching in fresh new ways. Each partner in this collaboration comes with an essential, yet distinct, perspective. Together, they can ignite student learning!

Fab Labs are closely aligned with MIT’s Center for Bits & Atoms where research into next generation tools and software, as well as fabrication work flows and processes is pushing up against digital-analog boundaries. CBA is charting a research road map that traverses the frontier of digital fabrication: from machines in a Fab Lab that make things, to machines that make parts of machines, to machines that self-reproduce, to building with digital materials, to materials that are programmable and can turn themselves into parts. As we progress along that research path, knowledge and best practices are disseminated throughout the Fab Lab network, making it a cutting edge laboratory for R&D.

The four qualities and requirements listed below altogether create an enabling environment that we call a Fab Lab. If your lab effort meets all these criteria, “Welcome!” If you feel you are in synchrony with the Fab Lab form and spirit, please use our logo in your fundraising efforts, and keep us informed of your progress. Please register your lab effort or new fab lab on the world map here. Here are the criteria we currently use for defining a Fab Lab:

1. First and foremost, public access to the Fab Lab is essential. A Fab Lab is about democratizing access to the tools for personal expression and invention. So a Fab Lab must be open to the public for free or in-kind service/barter at least part of the time each week, that’s essential.

2. Fab Labs support and subscribe to the Fab Charter (see below or click here)

3. Fab Labs have to share a common set of tools and processes. A prototyping facility is not the equivalent of a Fab Lab. A 3D printer is not a Fab Lab. The idea is that all the labs can share knowledge, designs, and collaborate across international borders. If I make something here in Boston and send you the files and documentation, you should be able to reproduce it there, fairly painlessly. If I walk into a Fab Lab in Russia, I should be able to do the same things that I can do in Nairobi, Cape Town, Delhi, Amsterdam or Boston Fab Labs. Essentially, it’s the processes and the codes and the capabilities that are important. Fab Labs typically include:

-A laser cutter that makes 2D and 3D structures

-A 3D printer

-A high-resolution CNC milling machine that makes circuit boards, precision parts, and molds for casting

-A large wood router for building furniture and housing

-A suite of electronic components and programming tools for low-cost, high-speed microcontrollers and on-site rapid circuit prototyping.

The critical machines and materials are identified in this list: http://inventory.fabcloud.io/ and there’s a list of open source software and freeware that we use online as well (embedded in Fab Academy modules here: http://academy.cba.mit.edu/classes/ ).

4. Fab Labs must participate in the larger, global Fab Lab network, that is, you can’t isolate yourself. This is about being part of a global, knowledge-sharing community. The public videoconference is one way to do connect. Attending the annual Fab Lab meeting is another. Collaborating and partnering with other labs in the network on workshops, challenges or projects is another way. Participating in Fab Academy is yet another way

Good luck and welcome!!!

What is a fab lab?

Fab labs are a global network of local labs, enabling invention by providing access to tools for digital fabrication

What’s in a fab lab?

Fab labs share an evolving inventory of core capabilities to make (almost) anything, allowing people and projects to be shared

What does the fab lab network provide?

Operational, educational, technical, financial, and logistical assistance beyond what’s available within one lab

Who can use a fab lab?

Fab labs are available as a community resource, offering open access for individuals as well as scheduled access for programs

What are your responsibilities?

Safety: Not hurting people or machines. / Operations: Assisting with cleaning, maintaining, and improving the lab / Knowledge: Contributing to documentation and instruction

Who owns fab lab inventions?

Designs and processes developed in fab labs can be protected and sold however an inventor chooses, but should remain available for individuals to use and learn from

How can businesses use a fab lab?

Commercial activities can be prototyped and incubated in a fab lab, but they must not conflict with other uses, they should grow beyond rather than within the lab, and they are expected to benefit the inventors, labs, and networks that contribute to their success.

You are on the front wave of a new, international movement in personal fabrication—and therefore you would be considered an “early adopter. The cheapest and fastest method to get a fab lab is to buy and assemble it yourself. This approach does require that you have some good expertise on hand to help you set up, install, debug and train. There are a few other ways to get a lab, but they are more expensive and require some contractual transactions.

Here’s the road map

The inventory of hardware and materials that we deploy in a full Fab Lab can be found here. This is the entire list of equipment, tools and consumables for a research grade fab lab. A fab lab currently comprises from $25-$65k in capital equipment and about $15-40k in consumables. The open source software or freeware we typically use can be found at our Fab Academy class site

The Fab Foundation can be your one stop shop when setting up a fab lab, and we have partners all over the world who can help. While we can’t do an over the phone consultation to get you started, we have plenty of resources here online. The Fab Foundation here in the US is designed to be a resource for purchasing and installing fab labs, training managers, sourcing difficult to access fab supplies, general fab lab network support, a portal to advanced technical education, and eventually an umbrella for matching funders to communities who want a fab lab and meet the network criteria. Let us know your of your interest, your application and your location and we can connect you.

MIT’s Center for Bits and Atoms is selectively entering into institutional partnerships for fab lab installation, training, and research. These agreements fund the development and deployment of enabling processes and projects. CBA will also continue to informally collaborate on establishing exceptional individual fab lab sites.

Outside of formal contractual programs or the network’s Fab Academy program for training there is a growing online paragraphs of information which addresses many questions, and a growing archive of tutorials online. (http://fab.cba.mit.edu — look under “tools”, “classes”, Fab Lab wiki, or the Fab Academy repository). Live help and support from volunteers in the network can be accessed through videoconference and our MCU online videoconferencing unit, where members hang out during the day and can help one another. It’s free and you can visit once you are set up to do so: http://fab.cba.mit.edu/about/video. There are also some good experts in the network now that you could contact directly to see if they would be interested (for a fee) in coming and helping you set up and train. I can connect you to those people if and when the time comes.

The best background on fab labs and the digital fabrication movement is Professor Neil Gershenfeld’s book: FAB: The Coming Revolution on Your Desktop–from Personal Computers to Personal Fabrication. (available on Amazon). It contains a wealth of information for you and is a good read.

You can also see some FAQ here

Another good resource for you that will give some background is Neil’s talk at the Library of Congress as seen on CSPAN.

As well as a few links to other information:

http://cba.mit.edu/events/05.07.Norway/

http://www.economist.com/science/displayStory.cfm?story_id=3786368

http://www.businessweek.com/magazine/content/05_18/b3931027_mz005.htm

1. Identify a host agency to host and take ownership of the Fab Lab.

The host agency could be any organization ranging from government agency, community organization, educational institution etc. The Fab Lab needs to be hosted, housed and owned by the right agency to ensure success.

2. Identify the right champion to lead this Fab Lab.

Very important. The successful Fab Labs are driven by the right champions. The champion needs to have passion for community development through technology deployment and should be respected by the community.

3. Finalize partnership/ contractual agreements Contracts and agreements

Including if appropriate Fab Foundation/ MIT, local partners, funders, service providers need to be put in place.

4. Secure funding for this Fab Lab.

Secure appropriate partnership for this Fab Lab. If you are interested in developing a network of fab labs–in South Africa there is a good model evolving around Public -Private- Partnership. Government funds equipment, host agency funds space, running and management expenses and firms pay for projects. Having said that this is a cumbersome process. The best would be to find the funder for a first Fab Lab and later pursue the SA model. If you get to this point the Fab Foundation/ MIT team can assist in budgeting, proposal writing etc.

5. Identify and prepare site.

Site selection is critical- in that it should be accessible to the community and should not deter potential users.

6. Procure, install and commission the Fab Lab.

7. Train the trainers (technical and management)

Proper training and handing over of the Lab is crucial for the success of the Lab. Trainers will be trained to train users and with our help you can put together a crash course of ‘How To Make (Almost) Anything’ with the early users.

8. Identify projects.

Starting with local problem solving, the Fab Lab will be integrated into the bigger Fab community and will have access to and participate in projects worked on globally and in a distributed manner.

9. Launch the Fab Lab.

Key community, government and private stakeholders can attend the launch to not only understand the Fab Lab concept but also witness the demos of project outputs.

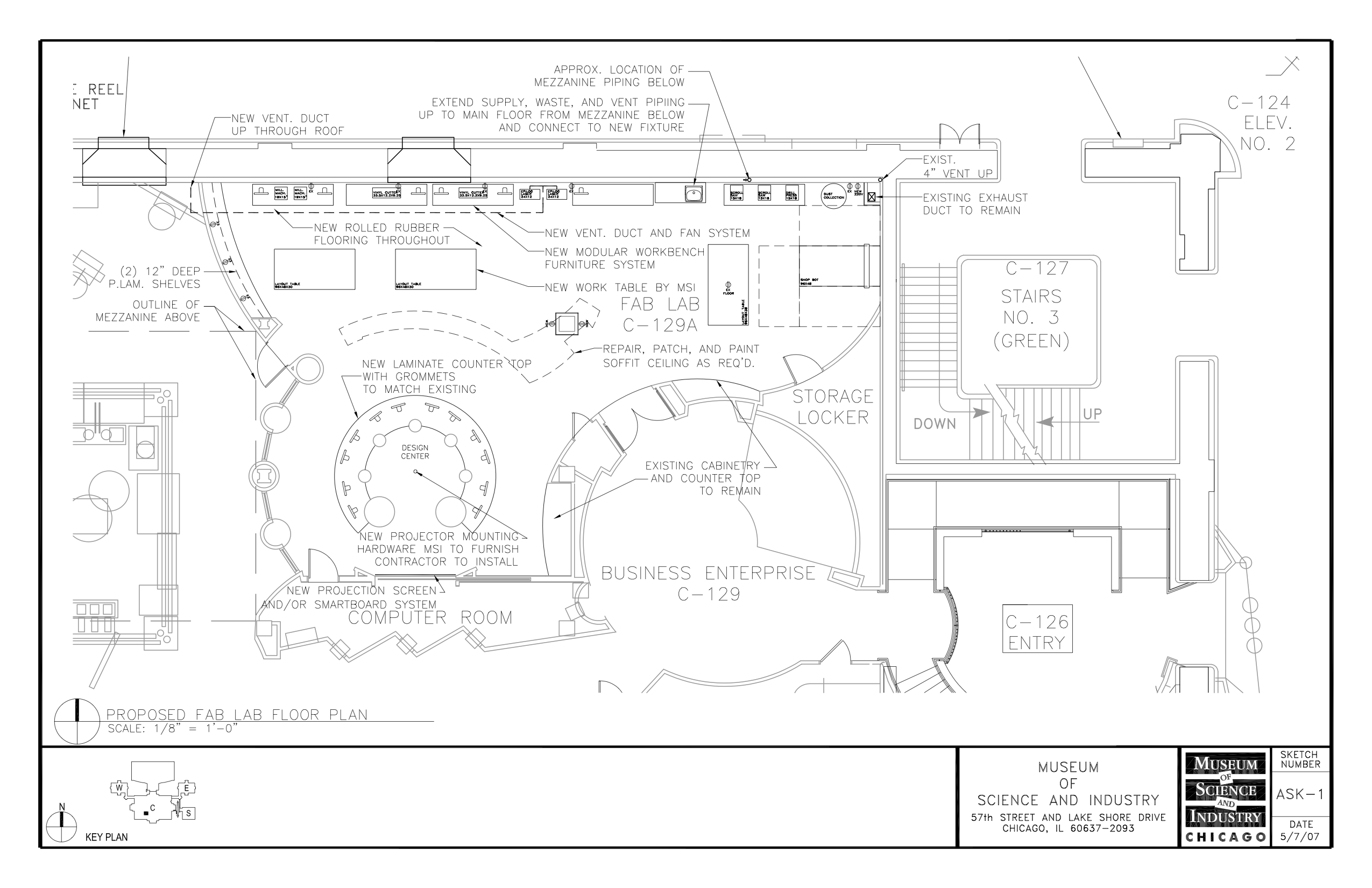

The lab we’ve been using as an example of the perfect space is the Chicago Fab Lab at the Museum of Science and Industry (MSI) — below is the PDF of the blueprint for you to refer to. The Chicago lab has two of each of the machines in it and is about 1900 square feet (approximately 177 square meters). For a laboratory with one of each machine, 1500 square feet, or 140 square meters should be sufficient.

This lab is designed to accommodate larger groups (about 20-30 users at a time), so it includes double the number of machines and tools—therefore more expensive that the usual Fab Lab . Depending on the focus and community of your Fab Lab you might want to design your lab similarly. We can talk through the design together, but even if you want to maintain the standard Fab Lab (one of each machine and tool) it would be good to use this layout as a model.

Looking at the blueprint, you will see a large circular shape entitled Business Enterprise—this is a museum exhibit just outside of the Fab Lab so ignore it. Adjacent to the circle is a semi-circle entitled “design center”. As 90% of a student or user’s time is spent designing on the computer, MSI invested in a design space for 12 users, plus a teacher/guru who can demonstrate using a projector and a powerful laptop computer on the screen at the front of the design center. This is also where videoconferencing for Fab Academy or meetings happens as well.

Behind the design center/screen wall is a computer room for IT purposes.

To the left of the design center there is another semicircular space. This is display space for the best or most interesting projects in the Fab Lab at the time.

To the left and behind the design center is the electronics workbench. That includes one set of bench test equipment, but two soldering stations and two programming stations (2 computers) and of course, electronic components and tools for two labs.

Along the back wall are two Modelas for making circuits and molds for casting. There is a computer designated for each Modela. (2 computers total here). Also along the back wall are two laser cutters, attached to 1 computer, and attached to an outside, roof ventilation system.

Toward the end of the back wall is a counter and sink with running water to handle casting projects and other projects that require water for processing or clean up. There are two long, empty counters along the back wall as well for work space and for use with some of the other kinds of tools, like a drill press and a scroll saw.

The right end of the lab, in the center of the lab there is a large open space for the large wood router and the associated computer and filter/blower. This is the one item that has special electrical power needs.

And finally you will see 2 or 3 large rectangles spanning the center of the room. These are purely workspace, places where students and users can spread out their projects as they work on them. Incredibly useful.

The one aspect of the space that all Fab Labs underestimate is the need for material and project storage. You need some significant space devoted to storing large pieces of wood and other materials, as well as cubby holes or shelving for student/user individual projects.

The following will get you fully fab lab ready, in other words, you can participate in Fab Academy, research collaborations and all the things a full fab lab is capable of doing. Please note that our computing environment is set up as primarily dual boot Windows/Ubuntu with most all the workflows in the Linux partition. We’ve listed here Windows-based, propriety software along with the open source and freeware that we typically use in fab labs, in case your institution or applications require Windows-based applications. But we believe in the open source approach, which aligns with our mission of democratizing access to the tools and knowledge for education and invention.

2D design, raster picture, scan

Vector

3D Design

Audio / Video

Simulation

Communities a Fab Lab might serve:

You could encourage experimentation and usage of the fab lab in the employee community by putting up a contest/challenge for them to use the fab lab. Something like– we’ll give a prize of money to the team that comes up with the best community project made in the fab lab and we (whichever organization is hosting) will help you implement it. For example, making benches for a community park, or desks for a low income school, etc

If you want to accommodate school groups of approximately 15 to 20 children per group, you should have two technical/guru support people working in the lab. If you have the extended hours I have outlined below, I think you need two shifts each day. So your staff would include:

“Function” is the community application and content of the fab lab. We’ve found that the fab lab needs to reflect the interests and needs of the community that hosts it. So each fab lab is different, based on the community where it resides Below are descriptions of 4 very different fab labs and how they function. These labs all try to balance financial sustainability with community needs and challenges.

1. Soshanguve Fab Lab

This fab lab is in a township in South Africa, just outside of Pretoria and is entirely about the community,and the social engineering around the community. During a visit several years ago to the township, we accidentally ran across a small community health center with a printing/resume service attached to it. It was run by a group of local youth called the Bright Youth Council, a team of young adults from the community who invested the time and fundraising capacity to build the Health Center. This amazing team provides both champions and gurus for the fab lab there. The print shop next door continues to provide printing and resume services (small commercial enterprise), but has now dedicated most of its computers to teaching children, teens, and adults to use computers and to design on computers. This is in essence the design center. Once users have designed something that they want to fabricate, they walk next door to the fab lab, where a small team of technical gurus helps them learn the machines, the electronics and the fabrication processes and workflows. This lab has recently expanded their services to assist users in prototyping for small business startup ideas. The startup prototyping is organized as fee-for-service, as yet unproved, but the demand for this kind of help, service and education is large in the township. This fab lab also plans to use the digital fabrication distributed education program Fab Academy, as an income stream to help sustain the fab lab operations. Fab Sosh currently get its funding from the CSIR/DST (government) and from large manufacturing companies with facilities nearby that are interested in workforce development and in corporate social responsibility.

2. Utrecht Fab Lab: Protospace

This fab lab, located in Utrecht, the Netherlands, is based around small businesses and entrepreneurial activities. It is a prototyping facility with a social mission as well. Protospace has 2 full time designer/fabricators on staff, one full time IT person, a full time administrator, plus a part time business manager/fundrasier. 4 days a week Protospace provides professional design and fabrication services for small businesses for a fee, A few days a week Protospace is open to the community for free access to the fab lab. Protospace is about 50% self sustaining.

3. University of Nairobi Science and Technology Park Fab Lab

This lab is about 3 years old and is the first fab lab to be integrated into a business incubator environment. It is situated on the University campus, but not associated with any one department, rather with the new Science and Technology Park initiative coming out of the government. The users are local inventors and entrepreneurs as well as recent University graduates from engineering. The fab lab is a terrific resource for the inventors and students to work on prototypes and ideas, and as importantly, to improve upon ideas already in process. This lab has about 8-10 small business ideas incubating. While only a few ideas originated in the fab lab, all of the inventors are improving their designs in the fab lab. The fab lab is also being used to train non-university people in advanced technical skills through Fab Academy. This lab is successful enough that the government wants to invest in a network of fab labs in this same context throughout Kenya. An interesting aspect of this lab is the relationship with the government, which backs the lab so far as to consider policy changes and supports to help it succeed, including import tariffs to protect businesses incubating out of the fab lab there. This lab is so far, entirely government funded, with plans to have the incubator take over financial support in the future.

4. MC2STEM High School Fab Lab

This is a formal education fab lab for high school students. Educators have put a full fab lab in the center of the specially designed STEM school and trained faculty in the skills to run the machines and design tools. In turn faculty and the principal have designed curriculum that incorporates the fab lab tools and processes in every discipline taught at the school (math, science, literature, English, history, technology, engineering, foreign languages). They have designed 10 capstone modules (each module is 10 weeks in duration) that address different overall concepts, and each subject takes both the content and fabrication skills into consideration in teaching the module. For example Electric Light is one capstone. Students design projects around the history of light, the use of light, the speed of light, the cultural uses of light, the technology and science of light, etc. This fab lab is co-located on a corporate campus (GE Lighting Company) such that GE engineers can come and work in the lab and help mentor students through projects, and through design, engineering and fabrication processes. In turn the students can apprentice and/or experience a real engineering environment and work with great professional role models for careers in science, engineering and technology. This is a public-private partnership between the GE Electric Company, the Cleveland public school system, with support from private investors.

The Fab Foundation can help you create a Fab Lab for your organization, university, school or community, but does not fund the creation of such labs or it's equipment. We are a non-profit organization that offers services and organizes project and programs for the global network but rely on funding or contracts ourselves.

Finding funding for your future lab

If you want to create a Fab Lab, there are several ways of funding it. People have succesefully started labs with their own funds, but that is a large investement. Most labs are either funded by organizations as part of a larger project or context (like in a university or company) or are funded with money from donor organizations. Fab Labs serve as community spaces, and offer education and business development opportunities - something that donors are often looking for.

Project and programs to fund the running of the lab

One of the programs we organize, the Fab Academy allows you to welcome students who pay to follow the classes in your lab. Similarly organizing paid workshops and training session can help fund your expenses. Many labs also charge fees for the use of machines, or have a subscription model. Some labs also sell products, or fabricate items for other organizations.

Costs of setting up a Fab Lab (with example budget)

The average cost of all the equipment of a standard lab (one that can participate in Fab Academy) is around 120 thousand USD. this does not include transport, installation and training and also depends on what size of machines you get (you can choose for a smaller or larger laser cutter, or CNC mill etc.) Below is an example budget. Might you want to get a better idea of the cost in your place, don't hesitate to contact us for more details.

Mobile Fab Lab

A mobile Fab Lab extends the hands on learning and capacities of a stationary Fab Lab to a larger audience of users!

What makes a Mobile Fab Lab?

To date most mobile fab labs are assembled inside a trailer and pulled by a heavy duty pick-up truck. As the network grows, so does the definition of mobile labs with machine specific carts, and short-term lending models being piloted.

The mobile Fab Labs have a standard platform which includes the suite of machines, and materials and equipment found in a stationary lab. This includes Laser Cutters, Filtration, CNC milling machine , MDX-20 Mini Mill, 3 D printers, Laptop Computers, Software (Sketch Up, Rhino, Corel Draw), Large format printer, an Electronics Workbench, Small tools for molding & casting, Molding and casting materials, Silk Screening materials, Documentation tools camera+ accessories), Power and Internet Cables, and Books.

The Role of the Network?

A history of a partnership

In 2009 Fab Foundation partnered with Lorain County Community College to construct the first Mobile Fab Lab outside of MIT. In 2015 3 more were constructed through this partnership. There were iterations in design, and man power with 3 PLTW students supporting the construction for pay and course credit.

Background and Description

In 2007 a group of curiously creative MIT students got together and developed the first mobile Fab Lab (1.0), their goal was to take the much celebrated course of making (almost) anything on the road.

In 2009 after several years of successful experience in using the Fab Lab at MC 2 STEM high school in Cleveland, the STEM partnership sought and secured funding from the state of Ohio to build the first mobile Fab Lab outside of MIT. In partnership with Lorain County Community College and Max Hayes High School, mobile Fab Lab 2.0 was built. The goal of mobile labs have been to extend the kind of high quality hands on learning in stationary Fab Labs to a greater audience through programming and outreach efforts. Mobile Fab Labs are a growing portfolio with 6 constructed and/or operating across the United States and several in the pipeline for construction. There are also a growing number being built abroad in Turkey, Saudi Arabia, and on the Amazon. All customized for the unique user experience of those communities.

Estimated Cost & Timeline

The estimated cost for a mobile Fab Lab is $298,000. The build of a mobile Fab Lab includes several phases (Design, Procurement, Construction, and Preparation & Training). These phases take approximately 6-18 months for completion depending on the project and the capacity of the network.

Features

The mobile Fab Labs built within in the network under the supervision of Fab Foundation have a standard platform which includes the suite of machines, and materials and equipment found in a stationary lab. This includes:

- Laser Cutters

- Filtration

- CNC Milling Machine

- MDX-20 Mini Mill

- 3 D printers

- Computers

- Software (Sketch Up, Rhino, Corel Draw)

- Large format printer

- Electronics Workbench

- Small tools/molding & casting

- Silk Screening materials

- Documentation (camera+ accessories)

- Power and Internet Cables

- Books

- Truck

- Trailer